Electrolysis, driven by electric currents, is a significant contributor to common causes of pipe corrosion. It alters fluid chemistry, leading to localized corrosion at high-potential areas, which can weaken structures over time, causing leaks or failures. Processes like galvanic corrosion between metals can also accelerate corrosion. Understanding electrochemical processes is crucial for preventing pipe corrosion and extending the lifespan of plumbing systems in both residential and industrial settings.

In the realm of plumbing maintenance, understanding the intricate dance of elements that contribute to pipe corrosion is paramount. This article delves into the common causes of pipe corrosion, exploring unexpected factors beyond what meets the eye. We dissect electrolysis and its impact on pipes, revealing how this process accelerates deterioration. Additionally, we scrutinize pH imbalance—a silent threat often overlooked—and its profound effects on water supply systems. Other surprising contributors, such as temperature fluctuations and contaminants, are also illuminated, offering a holistic view of corrosion prevention strategies.

- Electrolysis and Its Impact on Pipes

- – Understanding electrolysis and its role in pipe corrosion

- – Common scenarios leading to electrolisis-induced corrosion

Electrolysis and Its Impact on Pipes

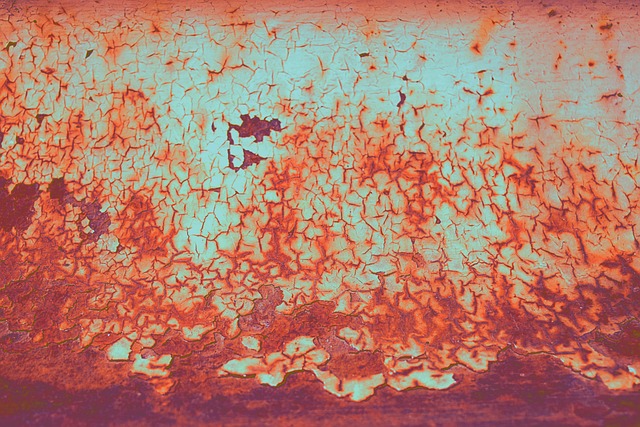

Electrolysis, a process where an electric current is used to facilitate chemical reactions, can significantly impact pipes and contribute to corrosion. When electricity passes through a pipe system, it creates an electrical field that alters the chemistry of the water or other fluids flowing through it. This phenomenon can lead to localized corrosion at certain points along the pipe’s surface, especially in areas with higher electric potential. Over time, this can weaken pipe structures and result in leaks or failures, making it one of the common causes of pipe corrosion.

In many cases, electrolysis is a hidden culprit in pipe degradation. It occurs not only in direct electrical contact scenarios but also through indirect processes like galvanic corrosion, where different metals in proximity experience accelerated oxidation due to their varying electrode potential. Understanding these underlying mechanisms is crucial when addressing and preventing common causes of pipe corrosion, ensuring the longevity of plumbing systems.

– Understanding electrolysis and its role in pipe corrosion

Electrolysis, a natural process where electrons flow through an external circuit, plays a significant role in pipe corrosion, one of the common causes of pipe degradation. When two different metals come into contact with each other and are immersed in an electrolyte (like water), an electric current is generated. This can lead to galvanic corrosion, where one metal acts as an anode and the other as a cathode, causing the more active metal to erode over time. For instance, if a pipe made of less noble metal, like iron, comes into contact with another metal like copper in moist environments, it can initiate electrolysis, leading to accelerated pipe corrosion.

Understanding this process is crucial when identifying and mitigating common causes of pipe corrosion. Many factors contribute to this issue beyond just electrolysis, including pH imbalance in water, which can alter the metal’s surface properties, making it more susceptible to attack. Other surprising causes include biological growths like algae and moss that can insulate and protect corrosive substances, as well as mechanical damage from debris or improper installation leading to early corrosion initiation.

– Common scenarios leading to electrolisis-induced corrosion

In many industrial settings, electrolysis-induced corrosion is a common cause of pipe degradation. This occurs when metal pipes act as an electrode in an electrolytic cell, facilitating the decomposition of water into hydrogen and oxygen. The resulting electrical current can lead to accelerated corrosion, especially in environments with high moisture content or where corrosive substances are present. For instance, pipes made of ferrous materials like iron or steel are particularly vulnerable when exposed to salt water or acidic solutions, as these substances enhance the electrolysis process.

Common scenarios leading to electrolisis-induced corrosion include coastal areas where seawater interact with pipe systems, leading to galvanic reactions that weaken the metal over time. Additionally, improper grounding or faulty electrical installations can create an unintended path for current flow, causing localized corrosion at certain points along the pipe’s surface. Even subtle pH imbalances in water supplies can disrupt the natural protective oxide layer on metals, making them more susceptible to corrosion when exposed to electrolysis conditions.

In exploring the intricate world of pipe corrosion, we’ve uncovered surprising causes beyond traditional culprits. From electrolysis, a subtle yet powerful force, to pH imbalances that disrupt the delicate chemical balance, understanding these factors is key to preventing widespread damage. By recognizing the common scenarios that lead to corrosion and adopting proactive measures, we can safeguard our plumbing systems from costly repairs and ensure longevity. Remember, addressing these hidden causes is essential in maintaining a robust and efficient piping infrastructure.