Pool table assembly requires careful unboxing and precise alignment for optimal gameplay. Leg placement, rail attachment, pocket installation, and table top securing are crucial steps. Assembly costs vary by table size, complexity, accessibility, and assembler expertise. To save on expenses, consider local installers, bulk discounts, clear communication of needs, and DIY options with modern tables.

Unpacking a pool table can be an exciting endeavor, but assembling it can feel daunting. This guide breaks down the pool table assembly process, helping you understand the steps involved and factors that influence the associated costs. From disassembly techniques to efficient reconfiguration, we explore tips to optimize your pool table setup, ensuring a smooth experience without breaking the bank. Learn how to navigate the pool table assembly rates and reduce potential expenses along the way.

- Understanding Pool Table Assembly Process

- Factors Affecting Assembly Rates

- Tips to Optimize and Reduce Assembly Costs

Understanding Pool Table Assembly Process

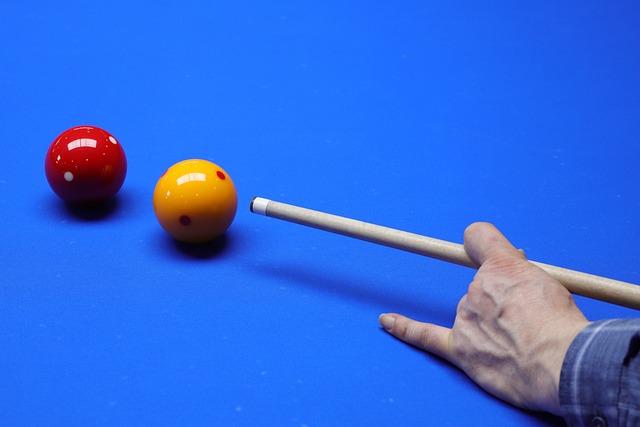

Understanding the pool table assembly process is crucial for anyone looking to install or set up a new table. The first step involves carefully unboxing the table, ensuring all parts are present and intact. This includes the table top, legs, pockets, rails, and cushions. Each component requires meticulous attention during this phase to avoid any damage. Once all pieces are laid out, the assembly begins with the placement of the legs, followed by the attachment of the rails and the installation of the pockets. The table top is then secured, ensuring a level surface for optimal gameplay. Every step in the pool table assembly process demands precision and care to guarantee a sturdy and durable structure.

The skill involved in pool table assembly goes beyond simple furniture construction. It requires an understanding of the intricate design and mechanics that make a pool table function seamlessly. Professional assemblers possess the expertise to properly align the rails, ensuring the cue ball rolls straight and true. They also take care to level the table, which is essential for consistent play and preventing warping over time. This attention to detail contributes to the overall quality of the final product, providing players with a superior gaming experience from the moment they bring their new pool table home.

Factors Affecting Assembly Rates

The cost and time required for pool table assembly can vary significantly, influenced by several key factors. One of the primary considerations is the size and complexity of the table itself. Larger tables or those with intricate designs and additional features may take longer to assemble, driving up labor costs. Additionally, the type of assembly service plays a role; while some companies offer basic assembly as part of their delivery package, more specialized services that include custom installations or disassembly for shipping can significantly impact the final rate.

Another crucial element is the accessibility of the installation location. Difficult-to-reach spaces or tight corners might require additional effort and specialized equipment, adding to the overall assembly time and cost. Furthermore, the experience and expertise of the assembly team cannot be overlooked. Skilled technicians with extensive pool table assembly experience can often work more efficiently, potentially reducing both time and labor expenses.

Tips to Optimize and Reduce Assembly Costs

To optimize and reduce pool table assembly costs, consider a few strategic moves. Firstly, pool table assembly rates can vary significantly based on location and the complexity of the setup. Opting for local assembly services can cut down transportation fees and ensure faster completion times. Additionally, many professional installers offer packages or discounts for bulk purchases or multiple tables.

Secondly, clear communication about your specific needs is key. Provide detailed measurements and layout plans to avoid miscommunications that could lead to costly errors or delays. Lastly, consider assembling the table yourself if budget is a primary concern. Many modern pool tables come with clear, step-by-step instructions and minimal parts, making DIY assembly feasible for savvy do-it-yourselfers.

Assembling a pool table is a complex process that varies in rate depending on several factors. Understanding these dynamics, from the initial disassembly and transport to final setup and calibration, is key to managing costs effectively. By optimizing your logistics and leveraging professional tips for efficiency, you can significantly reduce assembly times and expenses. Whether you’re doing it yourself or hiring experts, being aware of these variables will ensure a smoother, more cost-effective pool table assembly experience.